Today environmental and climate issues are on top of the agenda all over the world.

Seven years ago, this wasn’t the case, but a group of European ports acted and founded the project Dual Ports funded by the North Sea Region Interreg program.

The target was to develop and create a green and sustainable way of developing ports all over the EU to become a leader in the green transition within the Harbour sector in Europe.

The target of the project is to go green with a high focus on sustainability, reducing carbon emission and reducing the operating cost. The ports started to work with the green transition long before it became on top of the public agenda.

“The Dual Ports projects foresaw this year’s back when the project was founded – and it was the Sign of the Times – that we started out so yearly and made European ports ready to deal with what we know today,” says Jan Allaert, Port of Oostende, Lead Beneficiary, and project lead Dual Ports.

The key results were presented at a conference in Brussels Thursday June 16th, 2022.

According to the cumulative results calculated by the Hamburgisches Welt- WirtschaftsInstitut (HWWI) the operating cost have been reduced by 23 % – the target was 20%.

The total carbon emission has been reduced by 82 % – the target was 10 %.

“The key results clearly support the set goals years ago. We can make ports more sustainable and greener by reducing costs and carbon footprint. The overall results are impressing and a huge performance by all project partners,” says Jan Allaert, Port of Oostende, Lead Beneficiary, and project lead Dual Ports.

16 different pilots involving ports in Denmark, Germany, Scotland, Netherlands, and Belgium have been a part of the Dual Ports project during the last 7 years.

One of the partners is Port of Vordingborg in the southern part of Zeeland in Denmark.

In 2014 the port wanted to expand and be a greener port at the same time. The port joined Dual Ports and the pilot project was to prove that use of recycled products, such as contaminated soil, concrete, and excessive soil from building projects in the municipality.

“In 2023 the Port of Vordingborg is eight times bigger than when we joined the Dual Ports project in 2015. We wanted to be a green port and expand in a sustainable way. We have proved that is can be done by recycling of contaminated soil and residues. The carbon footprint is reduced by 20 % and the fourth port expansion that is in progress now is 100 % financed by use of recovered soil,” says Jan-Jaap Cramer, CEO Port of Vordingborg.

Project lead Jan Allaert from Port of Oostende stresses the future role for small and medium sized ports in Europe as leaders in the green transition and hubs for green and climate friendly energy production and transportation.

“The Dual Port project has been a major success and we have by far proved that ports play a vital role in the green transition. The project turned out to be a frontrunner in creating green and climate friendly solutions in ports around EU,” Jan Allaert, Port of Oostende, Lead Beneficiary, and project lead Dual Ports.

Note to editors:

DUAL Ports is a 6-year project, started in 2015.

It is 50% co-funded by the European Union and the European Regional Development Fund (ERDF) through the Interreg North Sea Region Programme 2014 – 2020, Eco-innovation priority.

DUAL Ports addresses the Programme objective of promoting resource efficiency and stimulating the adoption of new products, services and processes to reduce the environmental footprint of regions around the North Sea.

DUAL Ports will be measured in the concrete success of the pilots and the pilots’ transferability to other Regional Entrepreneurial Ports. The aim of the project is to collectively reduce carbon emissions by 12% and lower costs by 20%.

DUAL Ports aims to decarbonise Regional Entrepreneurial Ports (REPs)́ resources through a shared eco-innovation port programme that minimises their environmental footprint.

The objective of DUAL Ports is to

• reduce the environmental footprint of regional entrepreneurial ports,

• improve the sustainability of ports’ operational and administration resources,

• promote responsible growth and supporting eco-innovation-oriented development.

The project will ultimately enhance ports’ energy efficiency and performance, facilitating low carbonisation at reduced costs, with added value in terms of knowledge and investment.

Project Partners

- Port of Oostende

- Business Vordingborg

- Port of Vordingborg

- Port of Skagen

- Orkney Islands Council Marine Services

- ITM Power

- Fair Winds Trust

- Niedersachsen Ports GmbH & Co. KG Branch Emden

- Port of Zwolle

- Hamburgisches Welt- WirtschaftsInstitut (HWWI)

- Port of Hvide Sande

- Hvide Sande Fjernvarme A.m.b.A.

- Greenport

- Uppsala University

- Celtic Cruises Ltd

- Seabased

Floating solar, smart LED, integrated renewables-based systems, sustainable sedimentation and various other energy-efficient low carbon solutions implemented in EU port infrastructure and management practices will be presented at the free conference “DUAL Ports: sign of the times…” taking place in Brussels on 16th June.

COME, COLLABORATE, NETWORK, SHARE YOUR KNOWLEDGE and, if you are a company, inform the participating ports about your smart technologies.

The Dual Port project has been a major success and we have by far proved that ports play a vital role in the green transition. The project turned out to be a frontrunner in creating green and climate friendly solutions in ports around EU.

Jan Allaert, Project Lead

VENUE

The event will take place at the Representation of Lower Saxony to the European Union (Rue Montoyer 61, 1000 Brussels). To reach it from Brussels Midi take the Metro line 2 or 6 in the direction of “Elisabeth” and travel five stations to “Trône/Troon”. Get off there and follow the signs to “Montoyer”. Walk for 2-3 minutes as far as number 61.

Sign up for the conference here

Bright times for HelioRec, GreenPipe and the Port of Oostende!

The floating solar pilot implemented in the DUAL Ports project and its key characteristics were presented in the Business Focus Magazine. The floating panels are wind and wave-resistant. The patented “hydrolock” feature provides extra stability without the need to include more ballast, thus cutting costs for materials such as metal or concrete.

The power plants also use machine learning to predict energy generation for more efficiency and O&M optimisation. On top of this, the floating system is formed from recycled plastic, furthering its sustainability credentials. considering further expansion.

“We are looking to install more projects, around 10-50 kilowatts in size. We are also looking for more investors. In addition to this, we are looking at entering the US market”, said Polina Vasilenko, HelioRec´s CEO and founder.

See the full article here.

HelioRec won the Ocean Tribute Award provided by The Prince Albert II Foundation, Monaco and others

After testing its solar floating plat at the Port of Oostende together with GreenPipe within the scope of the DUAL Ports project, HelioRec was awarded the Ocean Tribute Award 2022 provided by THE PRINCE ALBERT II OF MONACO FOUNDATION (GB), German Ocean Foundation and Messe boot Düsseldorf.

“And the winner is: HelioRec,” Petros Michelidakis announces in the award ceremony film.

And his fellow competitor Frank Schweikert explains why both the jury and the public voted for HelioRec from Nantes:

“The French company scores with its environmentally friendly electric charging stations (ECS) for the maritime sector based on floating solar power plants. Unused water is converted into a clean energy source through a floating offshore solar cell system. The main objectives of the project are to save land area in a port area, generate a clean energy source, establish fast charging stations for electric vehicles and electric boats in the port, and realize new digital services for data prediction and optimization. Other concepts of the project are fast charging stations for electric vehicles and electric boats in the port. Another goal is the circular economy approach: recycled plastic is used to manufacture floating systems, reducing system costs and carbon footprint.”

More info here.

The hydrogen era of waterborne transport is getting nearer day by day at the Orkney Islands.

Zero carbon powered waterborne transport can reduce carbon emissions significantly.

Approximately 2.1 billion people use ferries every year, putting the industry on a par with commercial airlines in terms of annual users worldwide. To many cities and their citizens, travelling the waterways lies at the heart of everyday life.

While some cities have mandated the switch to ‘fossil-free’ biodiesel, these vessels are still omitting harmful particles that cause numerous health issues to citizens. Despite a widespread push to reduce emissions, ferries have long been neglected in the drive to create cleaner, greener public transport in cities.

The European Commission has set out its vision to establish 100 climate-neutral smart cities by 2030, but this cannot be achieved without investing in new emission-free waterborne transport solutions.

The hydrogen era of waterborne transport is getting nearer day by day. But the switch from conventional ferry transport to Zero Carbon ferries raises a demand for training the seafarers.

At the Orkney islands the very first cohort of seafarers has been trained to work on hydrogen powered vessels have passed exams on a new hydrogen course.

Seven crew members from Orkney Ferries have completed the course, equipping them with the necessary skills to work onboard ferries powered by hydrogen, a zero-carbon fuel.

This follows on from an earlier course completed by the crew which focused solely on the handling of hydrogen as a cargo.

“It all went well, and everybody passed exam. The feedback on the training was good and the training made the crew feel secure operating a ferry powered by hydrogen,” said David Hibbert, Technical Superintendent Orkney Islands Council – Harbour Authority.

The hydrogen seafarer course, believed to be the first of its kind in the world, was developed and delivered in Orkney by Orkney College UHI’s Maritime Studies department in collaboration with Orkney Ferries and the European Marine Energy Centre.

The course covered a range of theoretical and practical aspects relating to the use of hydrogen fuel on board vessels. This included storage under pressure, safe working practice around hydrogen gas, bunkering, firefighting as well as operational and safety management procedures specific to the hydrogen equipment installed on the MV Shapinsay.

“The crew members have been very engaged in the training being very open for innovative solutions and changes in the way you operate a ferry. These changes are a part of the green transition, and the seafarer are very openminded for this change,” said David Hibbert.

The firefighting training took place at one of the Orkney ferries and the crewmembers were trained in how to detect hydrogen fires which are almost invisible to the naked eye by using thermal imaging, as well as the very specific ways in which fires are fought when hydrogen is present.

“The firefighting training simulated a fire in the engine room on the ferry. We did that by heating the engine room to simulate that it was on fire and the crew members initiated the fire fighting. It worked quite well,” said David Hibbert.

The new training will be a requirement in UK waters for working on vessels using hydrogen as a fuel and is an addition to existing international requirements under the IGF code (International Code of Safety for Ships using Gases or other Low-flashpoint Fuels).

“Now we have a starting point of a conversion course to be implemented in the future, when crew members on traditional powered ferries will shift from operating conventional ferries to the Hydrogen powered ferries,” said David Hibbert.

New design of Hydrogen ferry

A new design of a hydrogen powered ferry is in the making. It’s planned to be put into commercial operation in 2023. The designs of a hydrogen vessel that will operate between Kirkwall and Shapinsay was revealed back in October 2021 and is awaiting final approval later this spring.

The Orkney islands produce more hydrogen than they can use, so the next logical step is needs so the logical step is to make transport fuel with this in the form of hydrogen. This potentially opens a significant new market for fuel cells, in the first instance the small lifeline ferries that serve remote islands and coastal regions which may also have similar renewable energy resources.

Facts – Port of Orkney – Ferry services

- 9 vessels

- 74 routes

- 13 islands served

- 20.000 sailings per year

Facts on Hydrogen

Hydrogen can be produced by electrolysis of water (H2O) by using an electric current to split water into its component parts of Hydrogen (H2) and Oxygen (O2).

Production of hydrogen uses renewable energy to power to the electrolysis of water.

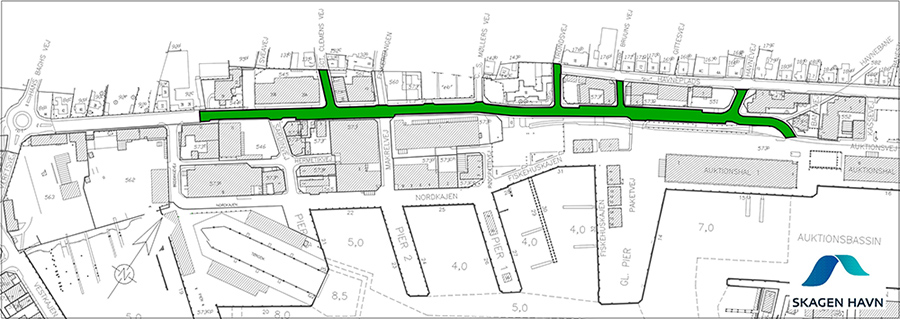

Traffic on Vestre Strandvej on Port of Skagen in the northernmost part of Denmark has become more environmentally friendly with new asphalt. The Port of Skagen now leads the way to a greener way for transport in and out of the port.

It is a new type of asphalt that saves both CO2 and absorbs the harmful NOx gases from the cars’ exhaust, which is the background to the greener transport road at the port.

The new asphalt was laid out on Vestre Strandvej in autumn 2021 as part of the EU project Dual Ports, and the purpose was to test an environmentally improving asphalt of 7,300m2.

“Overall, the experience has been good, and we have got a good road to drive on. It works well, and even though the asphalt is produced differently than conventional asphalt, you do not notice the difference,” says Jesper Rulffs, Business developer at Port of Skagen.

Jesper Rulffs is responsible for the project at Port of Skagen, a municipal self-governing port, and its an international commercial port as well as Denmark’s largest fishing port.

The new asphalt laid out on Vestre Strandvej and tested is NCC Green Asphalt. It is new asphalt that is partly produced from recycled asphalt. In addition to reusing asphalt, a new production method is also used that enables a lower production temperature.

This saves CO2 in the production process and saves 8,524 ton of CO2.

The total CO2 saving is 25% in the process of producing the asphalt and subsequently laying it out.

NOx filter on top of the asphalt

The new asphalt coating is applied with AirClean® concrete granules after laying and this made Vestre Strandvej in Skagen an active nitrogen oxide (NOx) reducing surface – that is, when the sun shines, the harmful NOx particles are converted into harmless nitrate.

NOx is also called nitrogen oxides and is the gasses generated by the combustion of gasoline and diesel in cars and ships. NOx consists of both NO and NO2. The gas NO2 is harmful to human health.

The active concrete granules are specially modified with titanium dioxide (TiO2), which acts as a catalyst together with sunlight. In this catalytic process, NOx particles are converted into harmless Nitrate (NO3-), which is washed away when it rains.

“We saved CO2 when we laid the asphalt and we reduced NOx air pollution using the special granules that were strewn onto the newly laid asphalt. So, all in all, we are satisfied with the result of the project,” says Jesper Rulffs, Port of Skagen.

Tests in Germany and China estimate an NOx reduction of between 15-25%, and it is at the same level at Port of Skagen.

This means that the new road surface on Vestre Strandvej will have the same air purifying effect as 70,000 m2 of forest.

“We do this as part of our sustainability profile at Port of Skagen. We are doing what we can to give the port a greener profile and for the world to become greener. In relation to the project of using environmentally improving asphalt, it is our conclusion that it is a good idea, but that overall, it is too expensive for us to do it without economical support,” says Jesper Rulffs.

The price of the environmentally enhancing asphalt is double that of conventional asphalt.

Many initiatives at Port of Skagen

Port of Skagen has been working for several years to reduce CO2 emissions from the port, and this has been done through three major initiatives.

- The port is electrified so that most ships can use shore power when ambient

- Port lighting has switched to LED lighting

- Cooling plant and lighting systems at the port’s fisheries auction have been replaced

The overall development of electricity consumption at Port of Skagen has increased, although the port’s area has doubled since 2014, the port’s own electricity consumption has decreased.

On the other hand, sales of electricity have increased due to the increased purchase of shore power by ships when they are moored.

In 2014, the port’s own consumption of electricity was 1.051,180 kwh, whereas by 2020 it has been reduced to 659,803 kwh, which is a reduction of 37 percent.

Port electricity sales have increased by 29 percent since 2014. The increase in electricity sales is largely because more ships connect to shore power, which is a sustainable alternative to the ship’s auxiliary engines.

According to the annual report from Port of Skagen in 2020, the port emitted 437 tons of CO2 in 2014, and this has been significantly reduced to 200 tons of CO2 by 2020.

FACTS ABOUT Port of Skagen

Port of Skagen is responsible for the operation and maintenance of 6.6 km of quay and 162 hectares of port area.

The port is Denmark’s largest fishing port and an active commercial port.

The port has five business areas:

- Fishing and processing

- Maritime service

- Goods and bunkering

- Commercial land lease

- Cruise and experience economy

Port of Skagen is ambitious and wants to support a responsible and sustainable transformation of society.

Sustainability means that they balance three sub-areas in terms of economic, environmental, and social sustainability. Sustainability for Port of Skagen means that they find the right balance between economic, environmental, and social sustainability.

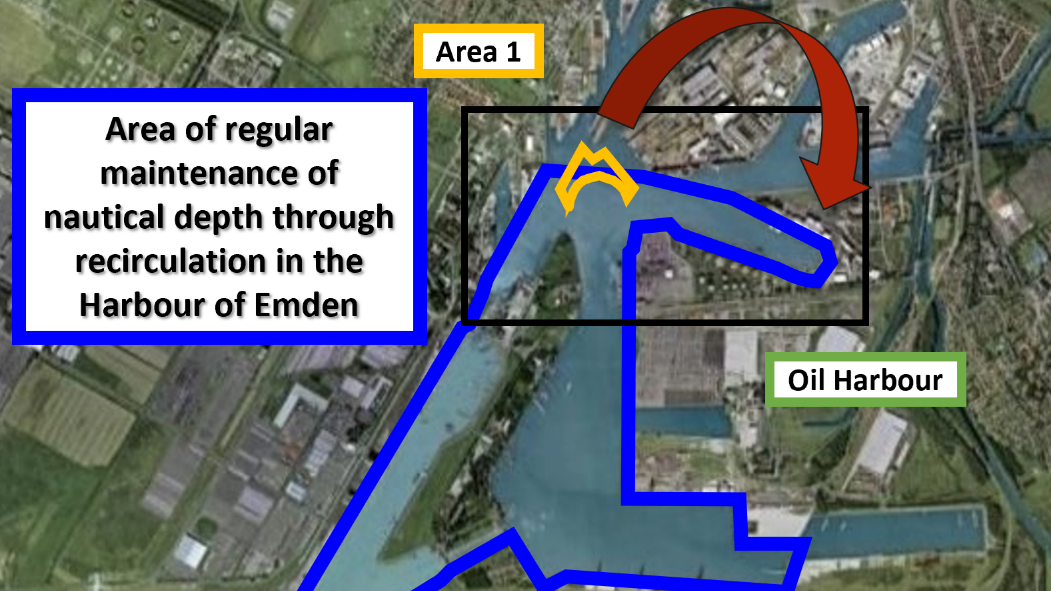

The German Seaport of Emden is facing a tough challenge:

Can they treat the environmental legacy pollution in the sediments and provide sufficient depth of water for port operation without spreading polluted materials to other parts of the harbor?

And do this in a climate friendly way and reduce carbon emissions?

During the process the harbor authorities must secure that any existing pollutants under no circumstances will be distributed to other port areas during the process.

This is a pilot project that began in 2020 with the extensive investigation of the actual pollution scenario by legacy contaminants in the harbour and culminated in 2021 in the kickstart of a field test and is still ongoing.

This is the question that the Port of Emden is trying to answer in their DUAL Ports Pilot Project where a promising in Situ pollutant treatment alternative is being investigated in a field experiment in a semi-enclosed section of the harbour.

Laboratory tests give strong indications that it works on a bigger scale.

Pollution from TBT

In parts of the port of Emden, the sediment presents environmental pollutants that entered the harbour mostly due to shipyard activities in the past decades, when several nowadays banned substances were still allowed. Near an old shipyard located at the inner part of the harbour, large quantities of PAHs (polyaromatic hydrocarbons) and TBT (Tributyltin) can be found.

A challenge the Port of Emden is facing is that the recirculation dredging procedures can only be carried out in areas where no pollutants are present in the sediment to be treated.

Any existing pollutants may under no circumstances be distributed to other port areas. This is not ensured by using the recirculation process used in the other parts of the port and therefore the potentially contaminated areas remained so far untouched.

This prevents the use of water depth conservation measures and thus the long-term use of certain parts of the harbour. Therefore, the harbour has seen a target to create an innovative, economically advantageous, and sustainable concept for the removal of pollutants in the port’s sediments, to maintain port operations there in the long term.

Fluid mud

The port is located at the mouth of the River Ems, and this causes problems with large deposits of estuarine sediments in the port. It significantly affects the depth of the port, and it is necessary on an ongoing operation to remove the deposits on the bottom.

This is done by a method where the material, that would otherwise settle, is recirculated, and is turned into a navigable mud layer, also called fluid mud, providing an increased water depth in the harbor.

The adapted trailing suction hopper dredger is used for this. This vessel dredges the very fine sediment into its hold, putting it in contact with the atmospheric air. The constant mixing of the material hinders the settlement and consolidation of it and thus makes it possible to sail through this created fluid mud layer.

A purpose-built vessel constantly sucks up the deposits on the bottom and releases it out again like fluid mud through which the ships in the harbor can navigate.

The process is very simple yet innovative. Normally, sediment on the bounds would be removed completely from the port and sailed away to be dumped either at sea – if not polluted or transported to a land depot. Both methods are expensive and burden the climate with increased carbon emissions.

Sedimentation and thus lower depth are a challenge all ports struggle with.

The Port infrastructure company Niedersachsen Ports has been using the fluid mud method in the port of Emden since 1992 and has good experience with it. Since 2000 the water depth maintenance of the harbour has been done solely by the recirculation process.

The question then is how the port can keep the depth in the areas contaminated with the pollutant TBT from a nearby shipyard without the contaminated mud being spread out in the rest of the port.

“The use of our already established recirculation process not only as a port maintenance method but also as a tool to facilitate the degradation of pollutants is very promising and suitable in our particular case, since we are dealing with organic pollutants in a relatively low to moderate concentration. The TBT will eventually disappear, but it will take a very long time to degrade. We would like to propose a process that stimulates the natural biodegradation of these organic substances, speeding up the degradation process of TBT,” explains Daniela da Rosa, Niedersachsen Ports, Emden.

How is it done?

The degradation of TBT by microorganisms in the environment is a naturally occurring process. Usually, it happens quite slowly because TBT is a man made, persistent substance that is very hard to degrade. A number of methods have been developed over the years for the removal of contaminants from sediments with varying cost ranges, waste generations, energy demands, transport requirements, and so on. Based on the scientific findings regarding contaminants degradation, the processes that take place during the recirculation process may facilitate the natural biodegradation of these compounds and therefore represent an in situ treatment approach worth investigating.

The enrichment of the fluid mud with oxygen from the air can potentially create more favorable conditions for the degrading microorganisms that are present in the system and cause higher microbial degrading activity.

TBT is more quickly transformed into less harmful products thorough the microbial metabolism activity.

The goal of the process is to create improvements of the conditions to optimize naturally occurring processes.

Test area established

A survey was conducted to identify which parts of the harbor that was suitable to conduct a test of the designed process. Area 1 was the least contaminated and other investigated areas were not suitable for the decided process.

Back in September 2021 a “bio-reactor” was set up located at the Oil Harbour (see illustration) to test the process.

“We moved a small part of moderately polluted material from area 1 and brought it into the oil harbour to test the effect of the recirculation process on the TBT degradation rates. The test and the monitoring will run until April 2022. We collect data every second week and analyze this data very thoroughly in order to hopefully be able to evaluate the effectiveness of the process by the end of the project. We have good reason to believe that this method works,” concludes Daniela da Rosa.

The pilot will continue this spring, and port of Emden expects that the outcome will be positive. The goal is to integrate area 1 of the harbor into the regular maintenance schedule to secure nautical depth.

The results of the project regarding the success in the treatment of TBT are still under evaluation and the process can take a longer time in comparison to conventional approaches. In terms of the financial and environmental aspects, however, this is a highly promising approach. The pilot project of Port of Emden is a part of the Dual Ports project, and the preliminary data clearly indicates that the targets in cost and CO2 reduction will be exceeded and that it will improve the economy at the Port of Emden.

“We hope the results of the test will produce meaningful insights for us and that it hopefully will represent the treatment alternative that the port is seeking. We hope to make use of the recirculation process to achieve sustainable decontamination of sediments whilst at the same time to carry on with the more resource efficient port maintenance strategy,” says Daniela da Rosa.

The Pilot project at the Port of Emden supports the overall goals of the Dual Ports project which is 20% operating cost reduction, 20% total cost reduction, and 10% emissions reduction.

According to the calculations carried out by the HWWI the pilot in Emden fulfils all targets by over 90% when the new method is compared with the conventional approach (extraction of the contaminated material, transport to, and depot at a specialized facility).

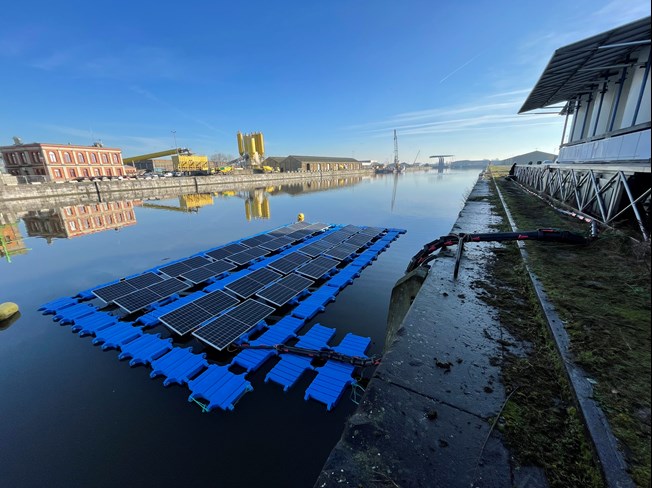

A unique pilot project with floating solar panels was launched in mid-January 2022 in the Belgian Port of Oostende. The purpose is to test whether the technology works and especially whether the floating solar power plant can cope in changing weather conditions.

Greenpipe, with great support from project partner HelioRec, is proud to announce the successful installation of the floating solar plant. The 10kWp floating solar plant was installed on the 14th of January 2022 in the Port of Oostende as a part of the DUAL Ports EU program.

Greenpipe is the project partner to Dual Ports with Heliorec as a subcontractor for the installation and analysis.

The French-based startup HelioRec was founded by Polina Vasilenko in 2019. She is also CEO of the innovative company:

“The project during the current challenging time has been successful thanks to the great support from all parties. It engaged 10 companies from 7 countries. The floating solar plant in Ostend port helps us to improve technology, step closer to commercialization, and contribute to building the clean and sustainable European ecosystem”, said Polina Vasilenko.

The 10kWp (130 m2) floating solar project was built as a key part of the DUAL Ports EU-funded initiative. The system is designed for 44 m/s wind speed and 2 m waves.

During storm Corrie and Eunice in February the installation was tested with high windspeeds from 22 m/s to 32 m/s – and the innovative power plant survived the test.

“During storm Eunice and the tough conditions, the power plant produced 6.4kWh and could supply energy for lighting and heater in the workshop at Port of Oostende” said Polina Vasilenko.

Difficult installation

The floating solar panels were assembled at the harbour and lifted into the water with a crane.

“It was quite complicated and difficult as this wasn’t standard procedure. The installation was successful because of a high-level professionalism of Oostende Port team, and shortly after the installation solar power plant started to produce power,” said Polina Vasilenko from HelioRec.

The power from the solar panels is used in a nearby workshop where an old boat is undergoing restoration.

Port of Oostende facilitated the test site at the harbour and Jan Allaert from Port of Oostende is looking forward to following the testing of the floating solar power plant as it has great potential with floating solar panels in and around ports.

“We are very focused on the blue economy and innovation of new zero carbon energy solutions and we are a hub for testing solar power. Solar power has a big potential, and it is important to test the various solutions,” said Jan Allaert, commercial manager Port of Oostende.

Test in two phases

The test in Port of Oostende is in two phases. Until July 14, the 130 m2 solar panels will be tested in the inner harbour behind the lock and after July 14th the floating solar power plant will be moved out of the inner harbour and onto the other side of the lock.

Among other things, the impact of the tidal difference will be tested here.

Energy storage added

Late February Heliorec added an energy storage system (ESS) to the floating solar power plant.

ESS is a specific type of power system that integrates a power grid connection with a Victron Energy Inverter/Charger, GX device, and battery system. It stores solar energy into a battery during the day, for use later when the sun stops shining.

HelioRec sees great potential in floating solar panels in and around ports and at high sea.

“Market potential is huge, and we are ready to launch large facilities into commercial operation. Our system is ready,” says Polina Vasilenko.

Solar panel reduces cost and emission

In this small-scale pilot preliminary results shows that the floating solar panels is producing more electricity than the workshop could consume.

From mid- to april 1st 486 kWh was consumed and that reduced carbon emission with approx. 115 kg and electricity costs with approximately 145 euro.

Project benefits:

- Saving land space

- Clean energy

- Grid dependence reduction

- System movement analysing and correlation

with energy production

See more details on the floating solar panels in this document

A new floating solar power plant has been set up in the Port of Oostende in Belgium.

Greenpipe, with great support from project partner HelioRec, is proud to announce the successful installation of the floating solar plant. The 10kWp floating solar plant was installed on the 14th of January 2022 in the Port Oostende under the DUAL Ports EU program.

Greenpipe is the project partner to Dual Ports with Heliorec as subcontractor for the installation and analysis.

Undertaking the project during the current challenging time has become successful thanks to the great support from all parties. It engaged 10 companies from 7 countries.

The 10kWp (130 m2) floating solar project was built as a key part of the DUAL Ports EU-funded initiative. The system is designed for 44 m/s wind speed and 2 m waves. It already produces 50kWh of clean energy to a nearby workshop.

HelioRec is proud to announce the completion of the new project. We installed the 10kWp floating solar plant on the 14th of January 2022 in the Oostende Port under the DualPorts EU program. Undertaking the project during the current challenging time has become successful thanks to the great support from all parties. It engaged 10 companies from 7 countries. The floating solar plant in Oostende port helps us to improve technology, step closer to commercialization, and contribute to building the clean and sustainable European ecosystem“, said Polina Vasilenko, Heliorec´s Founder and CEO.

Project benefits:

- Saving land space

- Clean energy

- Grid dependence reduction

- System movement analysing and correlation

with energy production

See more details on the floating solar panels in this document